Manufacturer of silencer systems for steam and gases behind safety , reducing and control valves

Blow-off and steam vent silencer for power plants and other industries

Silencers for blow-off, venting and other processes:

Control valve silencers

Safety valve silencers

Venting silencers

Special solutions

Valve exhaust lines are among the most intense sources of noise in power plants.

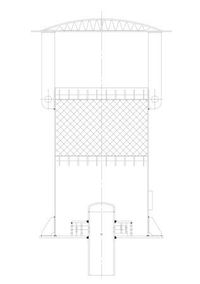

Blow-off silencers with / without pressure reducing stages reduce the noise generated by the steam pipes.

We manufacture specified blow-off silencers in the area of power plant and plant construction in carbon steel and stainless steel.

On the way to the atmosphere, the flow rate is reduced in the throttle stages / pressure reducing stages.

In the throttling stages / pressure relief stages, the medium flows through one or more perforated stages. The number of perforations in the individual stages is decisive and is specially designed for each silencer. Temperature and pressure are reduced via these throttle stages. Depending on the design and requirements, absorbent fillings follow.

Heira silencers are particularly characterized by robustness, low weight and freedom from maintenance. Accumulating condensate and rainwater is returned to the blow-out line via internal drainage systems. (Please ensure proper drainage at the lowest point behind the valve). We provide separate housing drainage on request.

For the design of the silencers, please provide us with the following information:

Medium and mass flow. Gas or steam volume per hour

Pressure upstream of the valve

Temperature upstream of the valve

Permissible sound pressure level, e.g. 90 dB(A) at a distance of 1 m.

Diameter of the inlet pipe , if specified.

Details of the permissible back pressure

Details of optional add-on parts such as rain roof or ring, bird screen, weld-on flange, clamps for on-site installation of trace heating

Silencer systems

Valve blowout lines are among the most intense sources of noise in power plants.

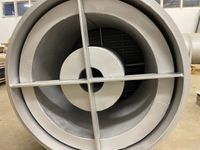

When a steam or gas stream exits through a pipe downstream of a safety, reducing and control valve, a turbulent zone forms downstream of the outlet. The jet mixes with the surrounding still air. In addition to the pressure surges and turbulence within the valves, this is the cause of noise generation. In order to achieve small cross-sections of the discharge lines, the pressure upstream of the silencer should be selected as high as permissible (15-20% of the set pressure in the case of safety valves). The pressure reduction in critical expansion stages as well as changes in direction and velocity convert the sound energy into heat. The reaction forces that occur are compensated by radially arranged bores.

Heira silencers are particularly characterized by robustness, low weight and freedom from maintenance. Any condensate and rainwater produced is returned to the exhaust line via internal drainage systems. (Please ensure proper drainage at the lowest point behind the valve). We provide for separate housing drainage on request.

The silencers are blast derusted and protected against corrosion with subsequent high heat resistant ethyl zinc silicate coating. The top coating is applied with silicone-aluminum.

For higher sound requirements than are the norm today, an absorption stage is added downstream of the expansion section. For reasons of corrosion resistance and abrasion resistance, this consists of a stainless steel wire mesh. The medium to be discharged flows through this knitted pack, thus converting the sound energy into heat by friction and absorbing it. The arrangement is either radial or as a package in the outlet opening. Splitter silencers for pressureless systems can also be manufactured on request.

Blow-out silencer / Blow-off silencer

Blow-off silencers for steam and gases downstream of safety and control valves and expansion valves.

Blowers

Blowers for natural gas compressor stations.

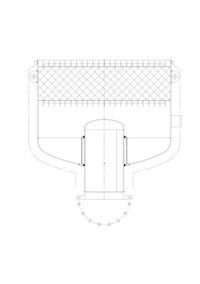

Flash tank

Flash tanks are used to remove condensate from pipelines, to drain boiler drums and for blowdown. They relieve high pressures and allow separation into steam and residual condensate.

In atmospheric flash tanks, the steam is discharged via a vapor line and a silencer above the roof. Pressure flash tanks discharge the steam into a system for further use. Gravity flash tanks operate quietly and stand absolutely still, so that complex support structures are not required. To ensure proper separation, it is necessary to consider condensate drainage systems as a whole.

About us

Heira Silencer GmbH was founded in January 2022 and, as the successor to Heiler GmbH, has over 20 years of expertise and experience in the field of sound technology.

Together with experienced process technicians and engineers, as well as a number of selected suppliers, Heira Silencer GmbH is a reliable partner for small and large projects in Europe. Production continues to take place exclusively in Germany.

The production is carried out by cooperation partners from the apparatus engineering sector.

The increasing quality requirements for power plant components are constantly being met by innovative solutions. The cooperation partners have all the necessary approvals for the manufacture and testing of pressure vessels and pressure-retaining equipment in accordance with PED 2014/68/EU.